Weathering the Elements: Durable Outdoor Furniture for Every Climate

- Jan 13

- 3 min read

Updated: Jan 28

As winter tightens its grip, craftspeople are turning their attention to projects that promise enduring beauty and resilience. For those dedicated to creating outdoor furniture, this means mastering the art of crafting pieces that can withstand the relentless forces of nature. Below we’ll delve into the critical considerations that separate ordinary outdoor furniture from exceptional, durable creations, focusing on material selection, advanced joinery, protective finishes, and innovative fastening solutions such as LIGNOLOC®.

The Artisan's Challenge: Crafting Longevity in Outdoor Furniture

The challenge for today's craftsmen is to reconcile the beauty of natural materials with the harsh realities of outdoor environments. Unlike indoor furniture, exposed pieces face constant UV radiation, temperature extremes, and biological threats. Consumers increasingly recognize that well-constructed outdoor furniture is a significant investment, not a disposable commodity. This demand creates a market for craftspeople who understand climate-specific challenges and can engineer solutions that extend product lifespan.

Different climates present unique challenges. Humid coastal environments breed salt spray corrosion and fungal growth. Arid regions with intense solar radiation degrade finishes and can make hardwoods brittle. Temperate climates experience cycles of expansion and contraction that stress joints and fasteners. Cold climates present frost heaves and freeze-thaw cycles that damage connections and finishes.

Material Mastery: Selecting the Right Wood for the Right Climate

Wood selection is the foundational decision in outdoor furniture making. As a hygroscopic material, wood constantly exchanges moisture with its environment, expanding and shrinking. Material selection must be climate specific.

· Teak is the gold standard, prized for its natural oils that provide water resistance and insect repellency. Properly maintained teak furniture can last up to 50 years or more.

· Cedar is a more economical option with natural resistance to rot and insects.

· White oak offers excellent structural properties and resists decay.

· Quarter-sawn white oak, with its superior dimensional stability, is ideal for resisting cupping and warping.

· Ipe wood, an exceptionally dense tropical hardwood, offers extreme durability but is more difficult to work with.

· Acacia wood provides a balance of cost, durability, and aesthetics.

Understanding wood movement is crucial. Tangential movement (parallel to growth rings) produces the most significant shrinkage, while longitudinal movement (along the grain) is negligible. Humidity is the dominant driver of wood movement, with high humidity causing expansion and low humidity causing shrinkage.

Protective Finishes: Shielding Your Creations from the Elements

Protective finishes are crucial for maintaining structural integrity and visual beauty.

· Spar varnish, originally developed for marine applications, combines long-oil formulations with flexible resins.

· Spar urethane offers UV protection and moisture resistance.

· Marine varnish provides a warmer aesthetic but requires more frequent maintenance.

· Water-based finishes offer lower cost and VOC emissions but may not perform as well in harsh conditions.

UV radiation is the most destructive environmental threat. UV blockers in finish formulations are critical. Pigmented finishes offer superior UV protection. Products specifically formulated for tropical hardwoods provide sophisticated UV protection systems.

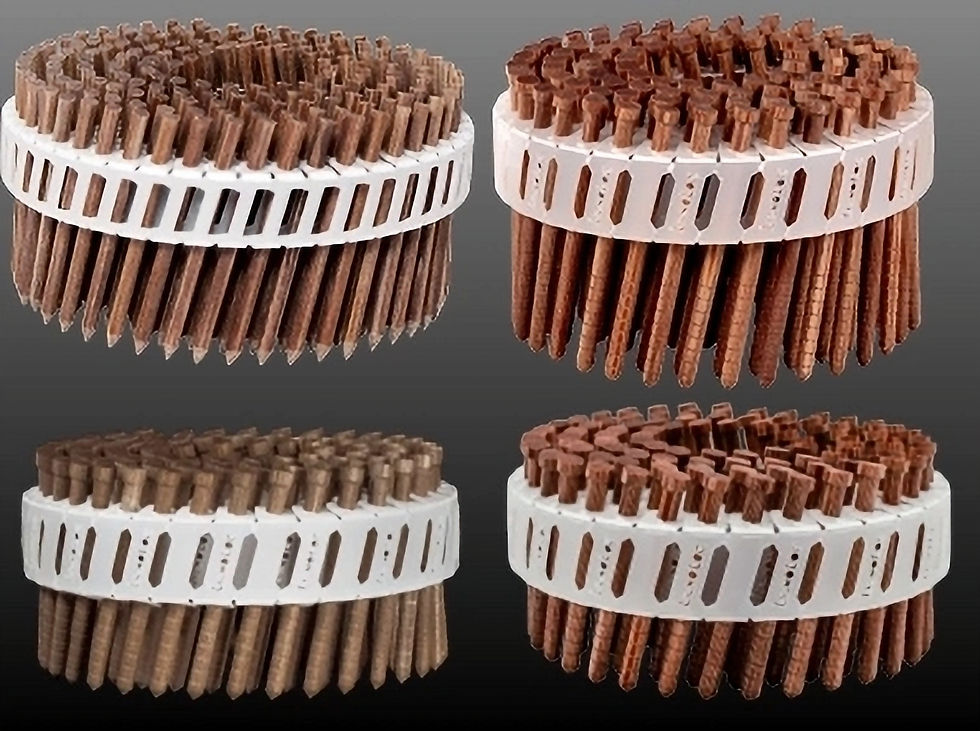

The Power of LIGNOLOC® Wooden Nails

Traditional metal fasteners present challenges, including heat conduction and corrosion. BECK’s innovative LIGNOLOC® wooden nails offer a sustainable alternative. Made from renewable beech wood, they achieve holding power through lignin adhesion, fusing with the surrounding wood. Pullout testing shows wooden nails can withstand over 500 pounds of force.

Wooden nails have a thermal conductivity of just 0.64 W/mK, preventing thermal bridging. They also resist corrosion, chemicals, and fungal decay. LIGNOLOC® nails reduce carbon dioxide emissions by 66% compared to metal fasteners. Used with BECK’s FASCO® pneumatic LIGNOLOC® nailers, you have the power to drive LIGNOLOC® wooden nails with no predrilling, speed, and precision.

Crafting for the Future

The demand for durable, sustainable outdoor furniture is only set to grow. By mastering material selection, advanced joinery, innovative fastening solutions like LIGNOLOC® wooden nails, and protective finishes, craftspeople can create pieces that weather the elements and stand the test of time. Embrace sustainable materials, explore mixed-material designs, and consider modular furniture concepts to stay ahead of contemporary trends.

Ready to elevate your craftsmanship? Explore LIGNOLOC® wooden nails and discover how you can create durable, sustainable outdoor furniture that lasts for generations. Visit our website to learn more and revolutionize your woodworking practices.